- admin

- Jun, 14, 2016

- Boulle Restoration, Marquetry, Restoration

- No Comments

18 months ago we started to work on a Boulle clock restoration for a gentleman back east.We received the clock piece by piece, starting with the top to show the process and what we could do to our client.First thing was bronzes removal

The lose brass elements where lifted and then, the fish glue in the cavities was rehydrated and removed, and the back of the brass elements were scraped clean.

Missing pieces are drawn by rubbing on a thermal fax paper

The missing elements are cut on brass or on pre CITES black backed tortoise shell.

Other pieces are cut

And glued down using sand bag and fish glue.

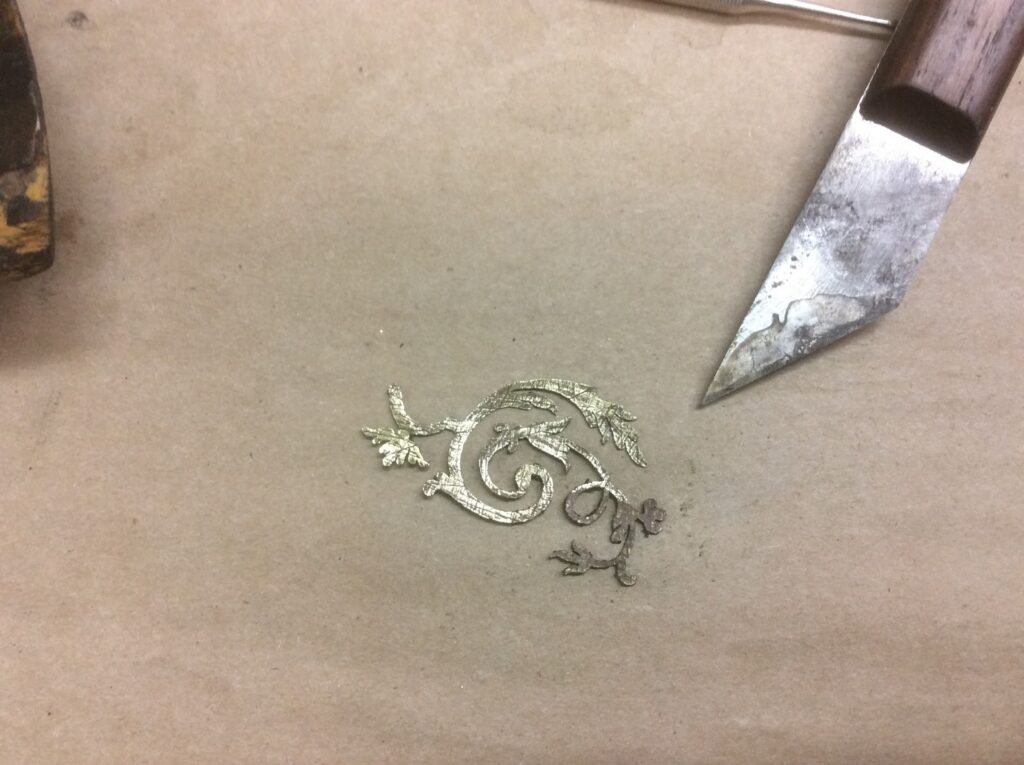

I also discovered the shell was engraved, something I have rarely seen

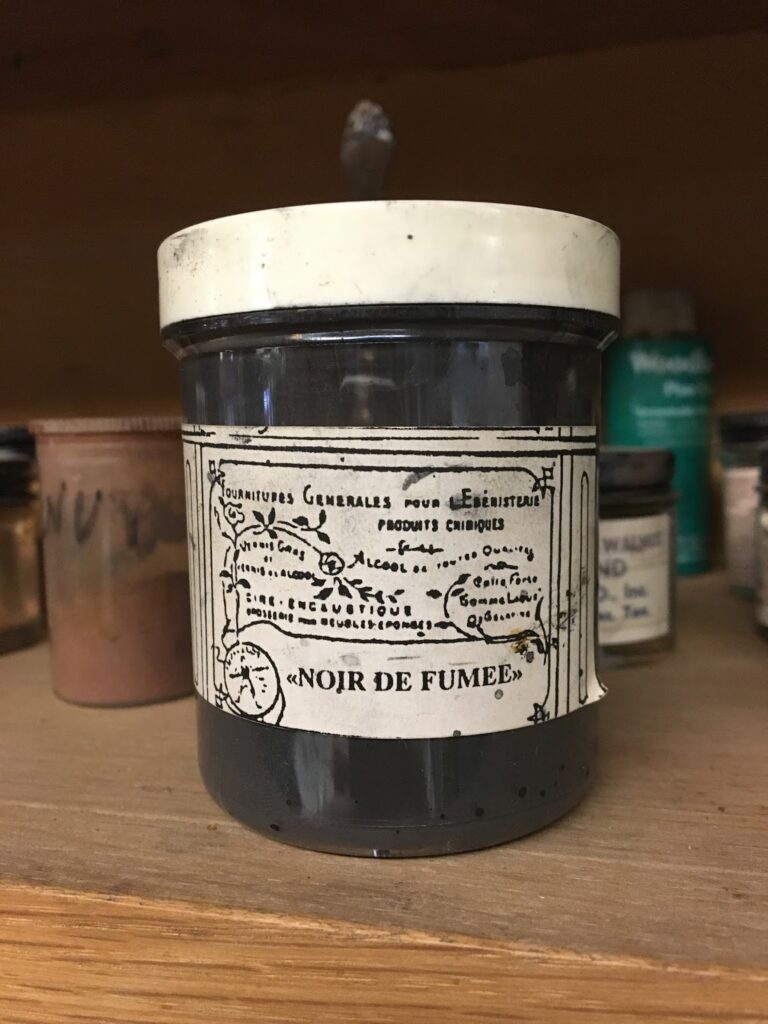

When eveything was restored, I used suit black to fill the brass engraving

Then the shell was re-engraved, the cavity filled with gold dust and french polished. It can be sometime tricky to french polish on brass ans the difference in temperature can bring condensation and give a milky consistence to the shellac.

The bronzes were cleaned and installed

working on those. The based was the first to arrive. It was the most damaged part of the clock and also the hardest to restore considering the curviness of the sides.

Like for the other part, I started by removal of the bronzes, lifting of the lose brass elements and cleaning of the cavities and the back of the brass pieces.

Like for the other pieces, I cut the missing elements out of brass and shell. I harvested some of the original horn from hidden under the bronzes for this purpose.

Cleaning and reglueing using sand bags

And Cawl for the rare flat spots

Before and after cleaning the brass

I recreated the missing elements using the little informations and inspiration from the rest of the decorative elements.

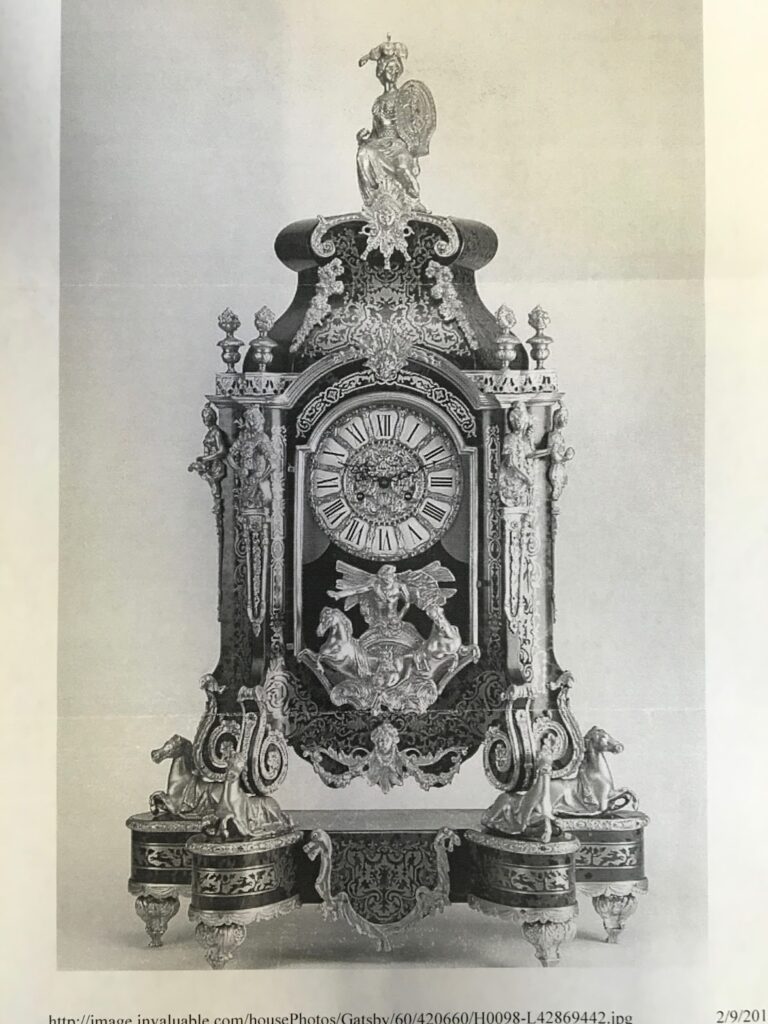

We ordered some missing finials in France using a picture of a similar clock

While waiting for the bronzes to be cast in France, I put the clock to the black at the same time of a decanter I was working on at the time.

Then the shell was re-engraved

And gold dust was laid in the engraving

Then french polish and bronze cleaning

And finally when the finials were received, we put it back together.

The body had a tendency to lean quite a bit to the back, so I added some dicreet washers on the back horses

And substantial ebony wedges on the top

Patrick also made a new top hinge for the door to make it work very well and a new key to fit the lock.

Now, it is ready to ship!